Need Custom Packaging Boxes?

Get Free Quote

We’re more than happy to assist in your packaging project.

Quality Control

StarSeed makes every box with extreme caution and efficiency.

Using top of the notch printing machine and box folding machine, we make

every step fast, accurate and countable. Enjoy the journey of a box here in StarSeed.

Everything About Striking Colors And Your Brand Image.

StarSeed is a center of knowledge, expertise and equipment for the development and manufacturing of paper packaging boxes. From paper to final boxes, we engage ourselves in building supply chain and upgrading our facilities, aiming at bringing both high quality and low price for your custom packaging boxes.

It All Starts From

Quality Raw Materials

We are holding accountable for every detail of your packaging box/bag. Our well vetted supplier network makes sure that what you order is always what you received.

We are Responsible for Color Presentation

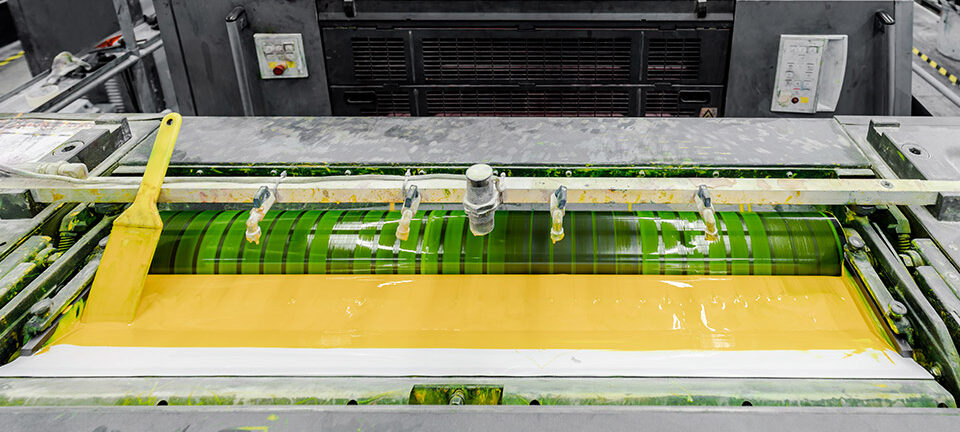

Printing Speed Control

Printing speed means profit for printing factory. Having the machine run too fast can cause problems such as position shift, inaccurate colors, higher waste rate and more.

It’s not the case here at StarSeed. We have the machine run at only 8000 -13000rpm while its maximum capacity reaches 20000rpm. Our years of practice proves that it is the perfect speed to balance productivity and printing quality.

Temperature & Humidity Control

Paper can absorb humidity and the temperature affects the time it takes to dry. StarSeed boasts rich experience in controlling optimum temperature and humidity for printing.

- Optimum temperature: 18°C – 25°C.

- Perfect humidity: 45% – 50%.

Doing so makes sure we are delivering vivid and solid color for every batch.

Control over Ink, Water, and Rubber Cloth

Top class machinery do not separately account for high quality printed boxes. Factors including quality of water, rubber cloth and ink serve as another critical part. Here at StarSeed, we run the production with years of experience:

- Water of pH value 15, perfect temperature at 8-13℃.

- Purchasing high volume of ink at one time to avoid color deviation caused by ink.

- Purchasing quality rubber cloth of better capacity for transferring colors.

All-in-One Color Checker

To deliver accurate color, our line of defense includes the most advanced all-in-one color checker equipped in our printing machine.

Right after the paper was printed, our operator randomly selects pieces from the bulk and verify the color with the color checker. Its auto calibrating feature also makes sure the printed colors will never go wrong on our side.

Sharp Eyes On Flaws

StarSeed has been investing heavily in the most sophisticated machines in order to attain higher quality, while we still keep human inspections to eliminate defective products that machines cannot detect.

By carefully checking the sample, examining the color, and weeding out those boxes with scratches or flaw, we end the manufacturing process with extreme care and caution.

Thoughtful Packaging and Delivery

Upon finishing the quality check process, our quality assurance practices do not end. We use sturdy corrugated boxes and plastic films to wrap and protect your bulk packaging boxes from drop and humidity caused by shipment.

Rest assured that we also take responsibility to make shipments lighter while simultaneously allowing greater quantities of product to fit on pallets, shipping containers, and, most importantly, retail shelves.